Are you looking for a unique touch to add to your packaging, product labels and printed documents? Embossing and debossing can be great solutions for giving special attention to your products. But have you ever wondered what the difference between embossing and debossing is?

This blog post will provide detailed overviews of embossing vs. debossing so that you can determine which is best suited for your branding needs. We’ll discuss when you should use embossing or debossing on your packaging or printing projects. Read on to find out more!

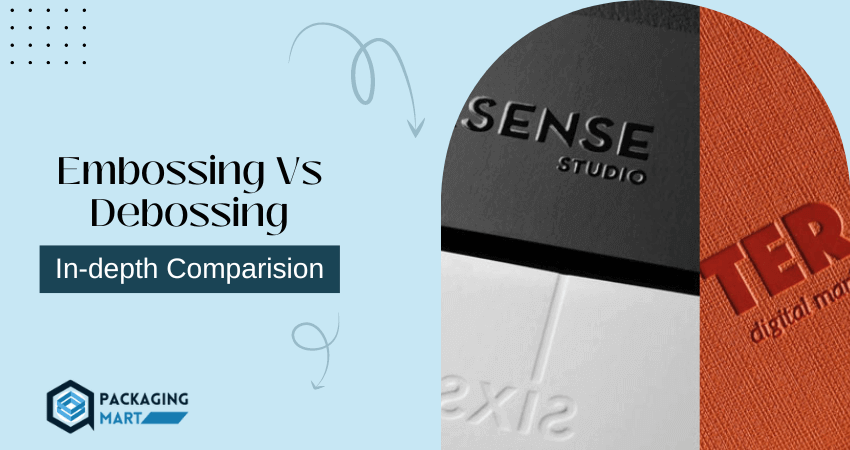

Embossing VS Debossing

Embossing is a process where an image or text is raised from the surface of a material. This provides a 3D effect and can be used for branding, decoration and even security purposes. Debossing is the opposite of embossing, where an image or text is pressed into the surface of a material.

Both techniques can be used on a variety of materials such as paper, wood, metal, leather and plastic. Embossing and debossing are often combined to achieve different effects and create a more eye-catching product.

The two processes are commonly used in branding, packaging and promotional materials such as business cards and invitations. Both embossing and debossing can add an extra level of sophistication to any project

Which is Best for Packaging and Printing?

When it comes to printing, embossing and debossing are two popular techniques used for adding dimension to a design. Embossing is the process of creating a raised surface on a printed material, often in the form of text or an image. Debossing is the opposite: it creates a depressed area in the material to create a three-dimensional effect. Both techniques are widely used for packaging, business cards, invitations and much more.

Embossing is often used to add an element of luxury or sophistication to a design, while debossing can be used to create a minimalistic look that stands out from the crowd. Embossed designs typically feature glossy areas and crisp edges, whereas debossed designs usually give off more of a matte aesthetic.

When choosing between embossing and debossing, it’s important to consider the materials you’re working with. Embossing works best on thicker materials, like leather or paperboard, whereas debossing works better on thinner materials such as cardstock. It also helps to determine which technique will be most cost-effective for your project.

Embossing is often more expensive than debossing, so a cost-benefit analysis can be really helpful. Embossing and debossing are excellent techniques for adding texture to your printed materials.

How are they different from each other?

Embossing and debossing are both ways of adding texture to a piece of paper or material. Embossing adds a raised design to the material that stands out from the surface, while debossing creates a recessed design that is sunken into the material. Also, embossing can create shadows and highlights, which adds dimension and depth to design, while debossing can create an elegant, understated look.

In general, embossing is a good choice for logos and text, while debossing is often used on paper goods such as invitations and stationery. It’s also important to note that embossing is mostly done with a printing press, while debossing can be done by hand.

Additionally, embossing requires an additional plate to create the raised effect, while debossing doesn’t require any extra plates. Overall, embossing and debossing are two distinct techniques that can be used to create a beautiful and unique design.

Related Article: Popular Types Of Paper Grades In Packaging

When should you use embossing or debossing on your packaging projects?

This depends on the type of product and message you’re trying to convey. Generally speaking, embossing is used to draw attention and emphasize a design element such as a logo, while debossing can help create an understated, sophisticated look. You may find that one or both techniques can be used to effectively communicate with your audience.

For example, embossing a product logo can give it a prominent presence on the packaging and create an immediate impression, while debossing text or a design element can add a subtle, luxurious touch.

Ultimately, the choice of embossing vs debossing will depend on what look you are going for and what type of impact you want to make. No matter which technique you choose, it should help enhance your message attractively and memorably. Embossing and debossing can both be used to create impressive results.

Examples of embossed and debossed designs

Embossed designs:

- Raised lettering on business cards, stationary and other branding elements.

- A raised logo on a leather briefcase or portfolio.

- A raised pattern on the cover of a book.

- Raised imprints on labels and product packaging.

- Logos on business cards.

- The raised words “Property of” on a laptop case.

- Elevated letters and images on jewelry boxes or photo frames.

Debossed designs:

- Brand logos on leather goods, such as wallets and belts.

- Textured patterns on a variety of surfaces including tile, wood, stone and metal.

- Product labels for a wide range of industrial items including medical equipment and tools.

- Personalized messages on jewelry and other keepsakes.

- Interior designs for cars and other vehicles.

- Unique patterns or symbols on glassware and other household items.

- Personalized artworks created with debossed techniques.

- Metal plates engraved with logos or special messages.

- Artistic designs on furniture, wall hangings and other decorative pieces.

- Company logos on promotional products such as pens and mugs.

Which is best for custom packaging designs? Embossed Or Debossed

Embossed and debossed designs both have their unique appeal. Embossing adds a raised texture that stands out, whereas debossing creates an indentation that adds a sleek, sophisticated look.

Depending on the product and packaging design, one style may be more suitable than the other. For example, luxury items and products that are meant to stand out may be better suited for an embossed design, while contemporary or minimalist designs may look better with a debossed design.

Ultimately, it is up to you to decide which style best fits your product and branding. Consider the materials used, customer base and overall packaging design before making a final decision. With the right combination of design elements, embossed and debossed designs can both add an attractive touch to your custom packaging.

Also Read: How To Make Your Own Packaging Box?

Final Thoughts

Debossing creates a visually appealing impression. On the other hand, embossed colors can take on a traditional elegance while providing a more subtle contrast. Embossing and debossing are both suitable for packaging and printing so the ideal choice depends on your personal project needs.

Consider what type of message you would like to send with the finished product to determine whether embossing or debossing is the better choice for you. Remember there is also no harm in combining these two processes for maximum effect as this can help create a more dynamic texture that stands out from regular flat printing.